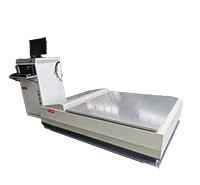

UV (UV light) weather test box/ultraviolet aging test box

Product Usage:

The destruction of materials in nature and humidity in nature causes difficult economic losses every year. UV accelerated weather test machines can reproduce the damage caused by sunlight, rain and dew. The equipment is exposed to the exposure of the tested material in the controlled sunlight and the interactive cycle of moisture, and at the same time improve the temperature to test it. The device uses ultraviolet fluorescence lights to simulate the sun. At the same time, it can also simulate the effects of moisture through condensation or spraying. It takes only a few days or a few weeks. The device can reproduce the damage caused by several months or years. The damage caused mainly includes degeneration, discoloration, decreased brightness, powder, cracking, vague, brittleness, decreased strength, and oxidation. The test data provided by the device has greatly helped the selection of new materials, the improvement of existing materials or the assessment of the composition of product durability. Equipment can predict the changes in the product will encounter outdoors

1. In the UVA light aging test machine, the fluorescent ultraviolet of ultraviolet lights can reproduce the impact of the sun, condensation and

The water spray system can reproduce the effects of rain and dew. In the entire test cycle, the temperature is controllable. Script

The type of test cycle is usually the dark humidity and cingling week of ultraviolet light and relative humidity at high temperature

Period; typical application in paint coatings, automobile industry, plastic products, wood products, glue, etc.

Simulation sunlight

UV rays in the sun are the main factor that causes durability damage to most materials. We use ultraviolet lights

Simten to the short -wave ultraviolet part in the sun, it produces very little visible light or infrared spectrum energy. We can be based on

Different test requirements choose different wavelength UV ultraviolet lights, because each lamp is in total ultraviolet radiation energy and

The wavelengths are different. Generally, the UV lamp tube can be divided into two types of UVA and UVB.

UV lamp tube

2. UVA-340 lamp tube: UVA-340 lamp tube can greatly simulate short-wave ultraviolet light in sunlight, that is, from 365

The wavelength range of 295 nanometer from nanometer to sunlight.

UVB-313 lamp tube: UVB-313 lamp tube short-wave ultraviolet light ratio ratio ratio that is usually filled with sun purple on the surface of the earth

The outer rays are strong, so that the materials can be accelerated to the greatest extent. However, the lamp may be made of certain materials

It does not meet the actual damage. UVB-313 lamp tube is mainly used for quality control and research and development, or extremely weather resistance

Strong material operation test.

UVA-351 Tube: Simulates the sunlight ultraviolet light of the window glass, it is the most aging of the test room material

efficient.

3. Wet and condensate environment

In many outdoor environments, the daily humid time of materials can be up to 12 hours. Studies show that this kind of household

The main factors of humidity are dew, not rain. This machine simulates the tide of outdoor through a unique condensation function

Wet erosion. During the condensation cycle during the test, the water in the bottom of the test room was heated to generate hot steaming

Qi and full of the entire test room, the thermal steam keeps the relative humidity of the test room at 100 %, and keeps one

Relatively high temperature. The sample is fixed in the side wall of the test room, so the test surface of the sample is exposed to the environment where the test room is exposed

in the air. The exposed side of the sample is exposed to the natural environment with cooling effect, resulting in the surface and outside of the sample

Temperature difference, the emergence of this temperature difference causes the sample during the entire condensation cycle, the test surface is always condensed Liquid water.

Since the outdoor exposure can be exposed to humid time for more than ten hours a day, the typical condensation cycle is average.

It lasts for several hours. This machine provides two humid simulation methods. The most applications are condensation methods, which are simulated households

The best way to erode outside.

4. Temperature control

In each cycle, the temperature can be controlled to one set value. At the same time, the blackboard thermometer can monitor the temperature

Spend. The improvement of temperature can accelerate the aging process.

It is also very important.

5. Water spraying system

For some applications, water spraying can better simulate the environmental conditions of the final use. Water spray in

It is very effective due to the heat shock or mechanical erosion caused by temperature drama and the scouring of rainwater. exist

Under certain practical application conditions, for example, in the sun, the accumulated heat quickly dissipates due to sudden shower.

At this time, the temperature of the material will change sharply, resulting in a heat shock.

Speaking is a test.

There are 6 nozzles in the spray system, and there are 3 on each side of the test room; the spray system can run for a few minutes

Then turn off. This short -time spray can quickly cool the sample to create the conditions for hot shocks.

6. Automatic control of irradiation intensity: Purchased

Optional irradiation intensity control options can obtain accurate and repetitive test results; optical strength control system

Allow users to set different light intensity according to different test requirements. The feedback loop device is accurate

Control the intensity of irradiation; at the same time, it can also extend the service life of the fluorescent lamp

7, temperature and humidity controller: PLC+touch screen automatic control.

8. Meet the standard:

ASTMG 153, ASTMG 154, ASTMD 4329, ASTMD 4799, ASTM

D4587, SAEJ 2020, ISO 4892