The three comprehensive test chambers mainly provide temperature and humidity change environments for scientific research and production units such as aerospace, aviation, petroleum, chemical industry, electronics, and communications. Perform temperature, humidity and vibration comprehensive stress screening tests on the whole machine (or components), electrical appliances, instruments, materials, etc., so as to evaluate the adaptability of the test product or evaluate the behavior of the test product. Compared with the effect of a single factor, it can more truly reflect the adaptability of electrical and electronic products to changes in temperature, humidity and vibration complex environment during transportation and actual use, and expose product defects. It is an indispensable and important test method in the whole process of the test.

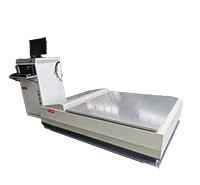

Composition of three comprehensive test chambers

The three comprehensive test box is composed of the following parts: test box body, motion connection system, control system, refrigeration/dehumidification system, heating/humidification system, air duct system, etc.

Three comprehensive test box functions

A comprehensive test environment that simulates three environmental factors in the same box.

Flexibility – The test chamber can be fitted with the user’s existing vibration equipment, or can be equipped with new vibration devices.

Versatile – Can be used as a stand-alone temperature/humidity test chamber to maximize your return on investment.

High performance, fast temperature change rate, can carry out accelerated stress testing of products.

Accept custom design to meet strict user requirements.

User-friendly control design, easy to use with the user’s other equipment.

The new design of the refrigeration system protects the compressor and ensures the refrigeration performance in the operation of the test chamber. At the same time, the refrigeration has low energy consumption and cost saving.

Humidity water filtration system to remove impurities and protect the test chamber. Program the controller.

RS-232/485 computer interface.

Redundant temperature limits & alarms.

3″ lead hole.

Stainless steel inner layer.

Viewing windows & lights.

Refrigeration pressure gauge.

Environmentally friendly refrigerant.

A vibrating device is attached to the membrane.

filter/cartridge.

Make studio size, temperature range, humidity range, vibration frequency, vibration mode according to user requirements

※Special specifications can be customized according to customer requirements