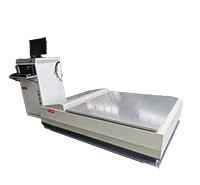

Semi-anechoic room/anechoic room/anechoic room

Usage description:

The semi-anechoic chamber is to establish a free sound field in a closed space (sound waves can only propagate freely in a 180° hemispherical position). In this space, the medium that propagates sound waves evenly extends in all directions indefinitely, so that the sound radiated by the sound source It can propagate “freely”, that is, there is no reflection of obstacles, and no interference from environmental noise.

Semi-anechoic chambers are used in various industries such as automobiles, electromechanical or electro-acoustics, and anechoic chambers, semi-anechoic chambers for acoustic testing of various products, anechoic chambers and anechoic boxes for testing of mobile phones or other communication products.

Main function description:

Semi-free field space

Free field means that when sound waves propagate in an infinite space, there are no reflectors and reflective surfaces. The main function of the anechoic chamber is to provide a free field space or semi-free field space for acoustic testing.

The free field radius is an index used to measure the size of the free field. For a well-designed anechoic chamber, the free field radius should be a distance from the center point to 1.0m from the wedge.

Background noise.

Another function of the anechoic room is to provide a low background noise environment to meet the requirements of the test environment. In the test frequency range, the sound pressure level of background noise should be at least 6dB lower than the sound pressure level of the sound source under test, preferably 12dB lower.

Cut-off frequency

In the design of an anechoic chamber, the lowest frequency with a wedge sound absorption coefficient of 0.99 is usually called the cut-off frequency. When the sound absorption system of the wall can guarantee a sound absorption coefficient of 9%, it can ensure that the anechoic room meets the free field conditions above the cut-off frequency. Measurements below the cut-off frequency can be corrected according to ISO 3746 and ISO 3747 standards.

design description:

After fully understanding the customer’s needs, our company designs the anechoic chamber according to standards such as ISO3745-2003, GB6882 and ISO7779. Acoustic indicators in the design include background noise, cut-off frequency, available space, vibration reduction, etc. On the premise of meeting the acoustic indicators, the design also considers the convenience of use, the split door, the installation and handling of the test piece (product), the ventilation condition, the wiring of the instrument, the monitoring conditions, the indoor environment, etc. On this basis, customers can purchase a professional detection system, use professional noise testing software, the computer performs noise source analysis, identification and noise source characteristics analysis, and automatically generates rectangular graphs, curve graphs, and statistical reports from the collected dynamic signals Wait. The noise of the tested product can be recorded and recorded, and the parameters and test analysis results can be automatically classified and archived. It can measure and analyze the noise of the product during operation. According to the comprehensive analysis of the mechanical parameters, electrical parameters, noise parameters and other parameters of the product in the running state, the qualification of the product can be effectively judged. It can test the vibration generated during the operation of the product, record the corresponding data, and automatically generate graphs, statistical reports, etc.

Hack

Since the 1940s, the principle of gradual transition has been applied to make porous (or fibrous) materials into cone-shaped or wedge-shaped sound absorbers, collectively called sound-absorbing wedge. When the sound wave is incident from the tip, due to the gradual transition nature of the sound-absorbing layer, the acoustic impedance of the material can be better matched with the acoustic impedance of the air, so that the sound wave is transmitted into the sound-absorbing body and is efficiently absorbed. So far, high-quality anechoic chambers at home and abroad have adopted a wedge structure as the sound absorber.

The sound absorption characteristics of the sound-absorbing wedge are related to the wedge length, filling material and cavity depth. The longer the wedge length of the same material, the better the low frequency sound absorption performance of the wedge. Adjusting the cavity review can also effectively improve the low-frequency sound absorption characteristics of the wedge structure

Verification of anechoic chamber

The main content of the anechoic room identification test is the space and frequency range of the free sound field. That is, at what frequency, what space range meets the conditions of the free sound field, and how big its deviation is. At the same time, the allowable error specified in ISO3745-2003 is given.

Attenuation curve of sound pressure level with distance in free field and allowable ± 2dB error

The anechoic room is not only a special laboratory for acoustic testing, but also an important part of the test system. In fact, it is also one of the acoustic testing equipment. Its acoustic performance directly affects the accuracy of the test. The anechoic room is divided into a full anechoic room and a semi-anechoic room. A room with sound-absorbing layers on all six sides is called a full anechoic room, generally referred to as an anechoic room. A room with sound-absorbing layers on only five or four of the six sides is called a semi-anechoic room. The main function of the anechoic room is to provide a free sound field space or semi-free sound field space for acoustic testing. The sound absorption treatment is the key to ensure a good free sound field performance after the anechoic chamber is built. Most of them use sound-absorbing wedge or flat-plate resonant sound-absorbing structure with strong sound absorption ability.

Standards compliant:

ISO3745-2003, GB6882 and ISO7779, GB/T42141, GB/T4214.4, GB/T3 767, etc.