The salt spray test chamber uses the method of salt spray corrosion to test the reliability of the respective corrosion resistance of the tested samples. Salt spray refers to the dispersion system composed of salt-containing tiny droplets in the atmosphere. One, many enterprise products need to simulate the damage caused by the surrounding climate of the ocean to the products, so the salt spray test chamber should be used. The salt spray test is divided into two types: neutral salt spray and acid salt spray. The difference lies in the different standards and test methods. They are called “NSS” and “CASS” tests, which are the most common tests in artificial three-proof climates. method.

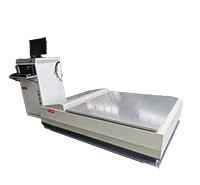

Box structure

The overall molding is welded at high temperature, corrosion-resistant, easy to clean, and has no leakage.

The tower spray system is equipped with a salt liquid filtration system, no crystallization nozzles, the salt spray is evenly distributed, and the sedimentation amount can be adjusted freely.

The box cover is made of transparent material to clearly see the test items and spray conditions in the box.

A water-tight structure is adopted between the box cover and the box body, and there is no salt spray overflow.

The circuit control board and other vital parts are fixed in the position that is convenient for inspection and maintenance, and the door-lock open side cover door is adopted, which is not only beautiful, but also convenient for maintenance.

internal structure

1. Spray device: tower sprayer with built-in glass nozzle, the spray is guided by the tower tube and then dispersed in a cone shape, and diffuses into the entire laboratory after uniform dispersion;

2. Adjustment of spray volume: increase the spray volume of the conical disperser on the spray tower, and reduce the spray volume;

3. Collector: The fine mist sprayed by the nozzle settles in a free fall manner, and one or several funnel cups with a surface area of ??80cm2 are built in to collect the salt mist, and after condensing into water, it flows through the conduit to the measuring cylinder outside the box;

4. Heating water tank: The water tank is attached to the bottom of the laboratory, which is used to heat the water to keep the temperature of the laboratory stable;

5. Shelf: It is made of plastic steel, with a single load bearing no more than 2kg. If it is scattered, it can bear the weight of less than 10kg. There are two rows of round holes on both sides of the shelf. use.

external structure

1. Test box cover: house-type beveled 110-degree see-through cover, which can clearly observe the indoor test conditions;

2. Isolate the water tank: use water to seal the box cover to avoid the leakage of salt spray;

3. Measuring cylinder: collect the spray volume of each test, 50ml each time is the highest scale;

4. Saturated air bucket: placed at the bottom of the control box, made of SUS#304 stainless steel plate, which plays the role of filtration, heating and humidification, so that the purified air reaches the saturated temperature and humidity and then sprays the nozzle. The saturator has automatic water replenishment. Features;

5. Pressure regulating valve: manually adjust the intake pressure and spray pressure. The intake pressure is controlled at 0.3mPa; the spray pressure is controlled at 0.07-0.17mPa. (The above pressure has been adjusted before leaving the factory, under normal circumstances, the user does not need to adjust it)

6. Pressure gauge: The pressure displayed by the pointer of the pressure gauge is the pressure when the air-saturated air barrel conveys the spray of the nozzle;

7. Water replenishment tank: automatic or manual replenishment of saturated bucket water;

8. Mist exhaust pipe: PVC hard plastic pipe with a diameter of 50, the pressure caused by the spray is expelled when the salt spray test box is working, and the excess water in the box also overflows.

Equipment material

The salt spray corrosion test chamber is generally made of PVC and PP.

When doing neutral salt spray test (NSS test) and salt spray test (SS test), PVC reinforced rigid plastic board is used.

PP board is used for acetate salt spray test (ASS test) and copper accelerated vinegar instinct test (CASS test).

PP board is more resistant to high temperature and strong corrosion than PVC board.

Control System

High-precision P.I.D. temperature controller, the error is ±0.1℃, Fuji, RKC, Honeywell watch (optional).

Continuous or periodic spraying optional.

All circuits are fitted with circuit breakers and all heaters have electronic and mechanical thermal protection.

Multiple system protection, safe and reliable to use. GB/T2423.17-2008 Environmental test of electrical and electronic products-Part 2: Test method Test Ka: salt spray

GB10587-89 Technical conditions of salt spray test chamber

natural environment

The artificial accelerated simulated salt spray environment test is to use a kind of test equipment with a certain volume space – salt spray test box, in the volume space, artificial methods are used to create a salt spray environment to age the product’s salt spray corrosion resistance performance and quality . Compared with the natural environment, the salt concentration of chloride in the salt spray environment is several times or dozens of times that of the general natural environment salt spray content, which greatly increases the corrosion rate. The salt spray test of the product will also take a long time to get the result. shorten.

Products conform to: CNS, ASTM, JIS, ISO standards. Salt spray test is to test the corrosion resistance of products after coating, electroplating, anodizing, anti-rust oil and other anti-corrosion treatments on the surface of various materials.

Adopt imported intelligent temperature control instrument. The instrument has a high degree of intelligence, multiple groups of PID operations and fuzzy control, fast tuning, and achieves smoother control output and higher control accuracy.

Using an automatic timing device, after the test laboratory reaches the predetermined temperature, it will automatically spray, and it will automatically stop when it reaches the time set by the timer.

The laboratory can also use a transparent top cover to monitor the spray status and the working status of the sample at any time.

The nozzle adopts a non-crystalline spray nozzle, and there is no risk of salt clogging.

There are double pressure adjustment and over-temperature protection devices.

Structural features

1. The inner and outer bladders are made of epoxy glass fiber reinforced plastic as a whole, which has the characteristics of light weight, corrosion resistance, high strength, no leakage, smooth surface, smooth and easy to clean.

2. The water-sealed form prevents the salt spray from overflowing, and the jacketed air duct is heated, so that the working room is heated up quickly and the temperature is distributed evenly.

3. The top cover of the salt spray box is designed with a top angle of 110~112°C, so that the condensed water in the box will not drop directly on the test sample.

4. The spray method is tower spray, and the spray tower is placed in the middle of the bottom surface of the studio. The material of the nozzle is made of quartz glass, the sprayed material is small, and the salt spray is evenly distributed by natural sedimentation.

5. The control system of the equipment is placed on the upper right of the box, which is convenient for users to operate. The panel is provided with a power switch, a mist exhaust switch, a spray transfer switch, two PID self-tuning digital display instruments, as well as the equipment running time timer and gap. The spray timer is also equipped with an over-temperature protector on the circuit board of the box.

※Special specifications can be customized according to customer requirements