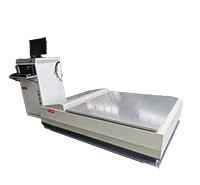

Temperature Shock Tester/Cold and Heat Shock Tester/Programmable Cold and Heat Shock Tester

Instructions for use:

This product is suitable for the safety performance test of electronic and electrical components and electrical products, as well as product reliability test, product screening test, etc. At the same time, through this equipment test, the reliability of the product can be improved and the quality of the product can be controlled.

Features:

All functions are controlled by computer. It is self-developed software with a good operation interface, which makes the user’s operation and monitoring more simple and intuitive. The hold function can keep the program you are running in the current state, and you can temporarily change this The value of the program segment, the time parameter can be set on the screen _, so that the cooling, heating, damper switching or blue-lifting transmission switching can be automatically carried out according to the set value. Control system: The main controller adopts imported dual-loop high-precision 7-inch color liquid crystal display touch key temperature controller.

Standards compliant:

GB/T2423. 1.2 GB10592 – 89 GJB15

Model CJ450T/F/S CJ600T/F/S CJ800T/F/S CJ1000T/F/S

Studio size D*W*H (mn) 450X 450X 450 600X 600 X600 800X 800X 800 1000X 1000X 1000

Sample Holder Dimensions DX y (mm) 320X 320 450X 450 650X 650 850X 850

Performance index Temperature range T: -20℃~200℃ F: -40℃~200℃ s: -60~200℃ (or others)

Temperature fluctuation High temperature room and low temperature room are both ≤±2℃

Sample area temperature ≤±0.5℃ (at constant temperature)

Sample area load 20kg/30kg/ 50kg (or other)

Temperature and humidity operation control system Controller 7-inch color touch screen (P.I.D +S.S.R. ) microcomputer integrated controller

Accuracy range Setting accuracy: temperature ±0.1℃, indication accuracy: temperature ±0.1℃, resolution: ±0.1℃

Refrigeration system Imported German Copeland water-cooled compressor unit compression refrigeration method

Circulation system Temperature-resistant and low-noise air-conditioning motor. Multi-blade centrifugal fan

Temperature conversion time from low temperature zone to high temperature zone or from high temperature zone to low temperature zone≤15S

Temperature recovery time ≤5min (related to temperature recovery conditions, including cooling water temperature, exposure temperature difference, constant temperature time, and sample weight)

Temperature shock method Vertical two-box method/vertical three-box method

※Special specifications can be customized according to customer requirements