Excellent performance, beautiful appearance, good reliability, easy to use and simple maintenance. It is an ideal choice for laboratory environmental test equipment

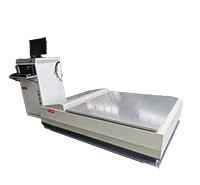

The mainframe, test control system and software of the pressure universal testing machine all use the most advanced technology at present. It is developed by the China-based testing machine combined with many years of technical experience and market demand. It adopts the international leading design concept and has the advantages of simple operation, stable and reliable performance. , which can meet the customer’s sample test needs to the greatest extent, and is the best choice for all kinds of metal and non-metal material sample tests.

The full-featured TestExpert.NET software provides high-precision, repeatable mechanical properties testing for materials, components, and finished products.

Meet individual or complex experimental needs

Meet the needs of fast and efficient quality control testing

Testers can easily create and complete test procedures, analyze data and generate test reports based on specific test needs

Applicable standards:

Provide high reliability testing solutions for metals, composite materials, building materials, etc.

According to the different characteristics of metal materials, we provide a complete set of test solutions to meet different test needs.

Fully meet the requirements of GB, ISO, ASTM, EN, JIS and other standards for metal testing (software)

GB/T 228-2010 ISO 6892-1 ASTM E8M EN 1002-1 JIS Z 2241-1998 Room temperature tensile test method for metallic materials

GB/T 4338-2006 ISO 783 ASTM E21 High temperature tensile test method for metallic materials

GB/T 7314-2005 ISO 4506 ASTM E9-89a Compression test method for metallic materials

GB/T 14452-93 ISO 7438 ASTM E290 Bending test method for metallic materials

GB/T 5207-1999 ISO 10275 ASTM E517 Test method for plastic strain ratio (r value) of sheet metal

GB/T 5208-1999 ISO 10275 ASTM E646 Metal Sheet Tensile Strain – Test Method for Hardening Index (n Value)

Provide high-strength, high-brittleness testing solutions for composite materials

Fully meet the requirements of GB, ISO, ASTM, EN, JIS and other standards for composite material testing (software)

GB 1040-2006 ISO 527-1 ASTM D638 Determination of Tensile Properties of Plastics

GB 1041-2008 ISO 604 ASTM D695 Determination of Compression Properties of Plastics

GB 9341-2008 ISO 178 ASTM D790 Determination of flexural properties of plastics

GB/T 529-2008 ISO 34-1 ASTMD624 Determination of strength of vulcanized rubber or thermoplastic rubber series

GB 9641-1988 ISO 1926 Test method for tensile properties of rigid foamed plastics

GB 20688-2007 ISO 22762-1 Test method for rubber bearings

GB 10654-2001 ISO 1798 Determination of tensile strength and elongation at break of polymeric porous elastic materials

GB/T 7124-2008 ISO 4587 Determination of Tensile Shear Strength of Adhesives

GB/T 3355-2005 Test method for longitudinal and transverse shear of fiber reinforced plastics

Provide high-rigidity testing solutions for building materials

Fully meet the requirements of GB, ISO, ASTM, EN, JIS and other standards for building material testing

GB/T5224-2003 ISO 16934 Steel strand for prestressed concrete

GB 15788-2005 ISO 10319 Geotextiles and related products Wide strip tensile test

GB 1936.1-1991 ISO 3133 Test method for flexural strength of wood

GB 328-2007 EN 13707:2004 Test method for building waterproofing membrane

GB 3098-2000 ISO 898-1 Mechanical properties of fasteners Bolts, screws and studs

GB/T 6569-2006 ISO 14704:2000 Test method for bending strength of fine ceramics

GB 18242-2008 EN 13707:2004 Elastomer-modified bitumen waterproofing membrane

JT 529-2004 ISO 291|3126|3127 Plastic corrugated pipes for stress concrete bridges

YB/T5004-2001 JIS G3537-1994 Galvanized steel strand

GB 3074.1-2008 Determination of flexural strength of graphite electrodes

JC 937-2004 Soft permeable pipe

Technical advantages:

Comprehensive test custom function management

User management: Users can be created and edited, with horizontal and vertical dual rights management functions, which simplifies the operation process for specific users.

Test process: Use Windows Explorer to set up test process freely. Each process includes three contents: control process, data acquisition and fracture detection. Arbitrarily complex experiments can be completed through multi-segment control without any modification to the program. Sampling and break detection can be set separately in the test.

Method preset: Multiple test methods can be preset. Once a test method is set, it can be called for one or more groups of tests without affecting each other.

Test standard: meet the selection of a variety of material test method standards (such as GB, DIN, ISO, ASTM, etc.), and support the International System of Units.

Powerful analysis and processing functions

Curve selection and graphic processing: You can select commonly used curves (stress-strain, load-deformation, load-time, load-displacement, displacement-time, deformation-time and other curves) to perform partial amplification of the curve (stepless amplification, No file classification), traversal, moving center point, automatic identification of feature points (elastic segment, yield point, etc.), multiple overlays, and also supports manual marking, result comparison, print preview and manual effective revision of data and other functions.

Automatic save: The test conditions and test data are automatically saved to the disk, and can be recalled when necessary without loss.

Result reproduction: The test results can be accessed arbitrarily, and the curve can be re-analyzed.

Complete report generation function

The print title and document can be set arbitrarily according to the requirements, and the calculation items in the report can be output optionally. Statistical values ??of batch samples can be output, whether to output curves or not, and output curve characteristics. Rich report calling, conversion and printing functions.

Provide high reliability testing solutions for metals, composite materials, building materials, etc.

According to the different characteristics of metal materials, we provide a complete set of test solutions to meet different test needs. Fully meet the requirements of GB, ISO, ASTM, EN, JIS and other standards for metal testing (software)

TPHS (Thick plate High stiffness) frame combination structure

High rigidity: The structure adopts a seamless heavy-duty frame structure design to ensure high rigidity, small deformation, and small error in repeated test results.

Large space: The test space is large, which is convenient for sample clamping.

High coaxiality: excellent centering and coaxiality, ensuring minimal lateral force influence under load (meet the coaxiality detection method specified in GB/T16491-1996 “Electronic Universal Testing Machine” standard, the United States Test Methods Recommended by the Society for Testing and Materials ASTM Standard E1012-5).

Drive: compact servo motor drive (electronic), powerful servo-controlled hydraulic actuation system (hydraulic)

Toothed belt drive: The transmission and deceleration all adopt the structure of toothed belt with screw pair, synchronous movement, higher efficiency, more stable and low noise

State-of-the-art measurement technology

Special sensor: Equipped with the latest high-precision load sensor for universal testing machine developed by Changchun Institute of Machinery (won the second prize of the National Science and Technology Progress Award), with high rigidity and high precision, ensuring stable and accurate results in high-strength tests and long-term tests.

Intelligent compensation technology: effectively avoid the influence of external environment changes and additional loads on the sensor; automatically compensate the influence of inertial force on force value measurement, and the dynamic measurement error within 50Hz is less than 0.5%.

Non-linear correction technology: It has the ability to resist eccentricity and performs non-linear correction to ensure accurate measurement results.

State-of-the-art control technology

High precision: true 0.5 level precision, after linear correction (with professional organization test report).

Closed-loop control: The first closed-loop control is adopted in China, the application of technology is more skilled, and the transition is smooth without impact.

Automatic protection: powerful boot self-diagnosis, multiple limit protection, circuit protection, deviation protection.

Automatic reset: force, deformation, displacement can be reset automatically or manually.

Automatic identification: It has the function of automatic identification of load cells and strain extensometers.

Automatic calibration: The installed force, displacement and deformation sensors can be automatically calibrated and the best range can be automatically selected.

Real-time debugging: Equipped with the unique powerful ADJUST debugging software, which integrates the setting, modification and storage of all parameters (sensor, machinery, control, PID), and real-time debugging combined with real-time curve drawing.

Optional touch test system

Main specifications and technical parameters:

Specification model YDL300 YDL500 YDL600 YDL1000 YDL2000

Test force Maximum test force 300kn 500 kn 600 kn 1000 kn 2000 kn

Force measurement accuracy Within the range of 2% to 100% of the maximum experimental force, the accuracy is ±0.5% and ±1% of the indicated value.

Deformation Deformation measurement accuracy is ±0.5% of the indicated value within 2% to 100% of the extension measurement range

Displacement Piston stroke (mm) 150 200

Displacement measurement accuracy ±0.5%

Speed ??Speed ??accuracy ±0.5%

Clamping range Round sample Φ10~Φ32 Φ13~Φ40 Φ10~Φ60 Φ20~Φ70

Plate sample 0~15 0~30 0~40 15~50

Bending test bench Lower fulcrum span 30-300 (mm) 50-300 (mm)

Width of bending support 140 (mm) 160 (mm)

Mainframe Spacing between two pillars 430mm 470mm 550mm 640mm

The maximum distance between the drawing chucks (including the piston stroke) 650mm 700mm 700mm 750mm

Mainframe dimensions (MM) H.W.D 2150×850×580 2280×800×580 2550×1200×710 3000×1220×828

Maximum distance between upper and lower platens 500mm 560mm

Hydraulic source size (mm) 970×700×850

Host weight kg 1200 1700 1700 3300 6800

Power of the whole machine Main engine 220V, oil source 380V, ≤4.5kW Main engine 220V, oil source 380V, ≤5kW

※Special specifications can be customized according to customer requirements

Copyright Guangzhou Meiyifeng Testing Equipment Co., Ltd.