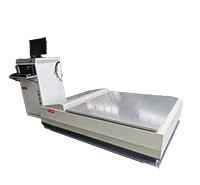

GDC series programmable constant temperature and humidity testing machine/constant temperature and humidity test chamber/Constant temperature and humidity test chamber/programmable humid heat alternating test chamber/thermostat/constant temperature and humidity chamber

Instructions for use:

This series of products are widely used in aviation, aerospace, information, electronics, instruments, meters and other industries, used for accelerated temperature tests and constant temperature tests of electrical and electronic products, materials, parts, equipment, etc., to test their various performance indicators, In order to evaluate the behavior of the sample under given environmental conditions.

?

Features:

- The box body is processed and formed by CNC machine tools, and the shape is beautiful and generous.

- The large observation window is equipped with a light to keep the inside of the box bright, and the tempered glass embedded in the heating body is used to clearly observe the situation in the box at any time.

- Double-layer high-temperature-resistant high-tension sealing strips are used between the door and the box to ensure the airtightness of the test area.

- The left side of the box is equipped with a test hole with a diameter of 50mm, which can be used for external test power lines or signal lines. (Aperture or number of holes must be added when ordering).

- Ingenious air duct structure, low noise and good temperature uniformity.

- Imported refrigeration units, key accessories are imported from international famous brands to improve operational reliability.

- GDC series adopts professional temperature controller, and the temperature is displayed directly.

- GDC series adopts LCD color liquid crystal touch screen program control; the screen operation is simple, highly user-friendly operation, easy program editing, no need for key input, the screen directly touches the options. The Chinese interface supports English at the same time, with multiple sets of multi-segment programs, and the maximum time setting for each segment is 99 hours and 59 minutes. Connection programs are not limited. The system is fully automated and easy to operate, which effectively solves the problem of operator learning and training.

- With the function of automatic calculation, it can randomly control the temperature change conditions, so that the temperature control is more accurate and stable.

- The multi-blade air blower is used for strong air circulation, avoiding any dead angle and making the temperature distribution in the test area uniform.

11.The air outlet and return air are designed to circulate in the air duct. The air pressure and wind speed meet the test standards, and the temperature can be stabilized quickly at the moment of opening the door.

- The heating and cooling systems are completely independent, which can improve efficiency, reduce testing costs, increase service life, and reduce failure rates. 2

- GDC series display in Chinese all the fault points of studio over-temperature, compressor overload, over-pressure, fan overload and wrong phase, which is convenient for maintenance. There is a compressor delay protection function.

- Optional remote monitoring computer and software, the upper computer implements redundant design, can be connected to a PC computer, and realizes paperless recording. . The host machine is turned off and does not affect the system control.

| Standards compliant: | IEC60068-2-1?” Environmental testing – Part 2-1: Tests – Test A: Cold” IEC60068-2-2 “Environmental testing – Part 2-2: Tests – Test B: Dry heat” IEC60068-2-78 “Environmental testing – Part 2-78: Tests – Test Cab: Damp heat, steady state” IEC60598-1?“Luminaires – Part 1: General requirements and tests” IES LM-80-08 “Approved Method: Measuring Lumen Maintenance of LED Light “ Etc. |

| Model: | GDC80B GDC120B GDC150B GDC225B GDC408B GDC800B GDC1000B

T/F/S T/F/S T/F/S T/F/S T/F/S T/F/S T/F/S |

Technica performance:

| Temperature range: | T-type: -20℃~+150℃(+150℃)

F-type:-40℃~+150℃(+150℃) S-type: -70℃~+150℃(+150℃) |

| Humidity range: | 20%~98% |

| Uniformity Temperature: | ±2℃ |

| Control accuracy Temperature : | ±0.3℃ |

| Heating time: | -20℃~+150℃?takes about 35?minutes;

-40℃~+150℃ takes about 45 minutes; -70℃~+150℃ takes about 60 minutes; |

| Cooling time: | +20℃~ 20℃ takes about 45 minutes;

+20℃~ 40℃ it takes about 55 minutes; +20℃~-70℃ takes about 80 minutes; |

| Inner box size : | 80L;120L;100L;150L;300L;500L;1000L(liter) |

Controller Programmable touch screen temperature controller

Structural material Inner box: first-class mirror stainless steel Outer box: stainless steel matte line treatment (or high-quality carbon steel plate + phosphating electrostatic spray treatment)

Refrigeration system Air-cooled fully enclosed compressor imported from Europe and the United States, environmentally friendly refrigerant

Water-cooled fully enclosed compressor imported from Europe and the United States, environmentally friendly refrigerant

Safety protection device Compressor overheating, overcurrent, overpressure protection. Heating dry burning protection. Leakage protection

Standard accessories: Observation window, 1 test hole B50X, 2 sets of up and down adjustable sample holders, 1 set of lighting

Power supply AC :?220V±10% 50Hz AC3?380V±10% 50Hz

Optional accessories RS485 communication interface, micro-printer, recorder.

※Special specifications can be customized according to customer requirements

Copyright Guangzhou Meiyifeng Testing Equipment Co., Ltd.