- ? Adhesion or adhesion tester

? Compression tester

? Creep and stress relaxation tester

? Drop or impact tester

? Ductility tester

?Fatigue tester

? Impact toughness tester

? Shear Tester

? Tensile tester

?Vibration tester features - feature

- ? ASTM defines adhesion as a kind of interfacial force, which may be caused by valence, interlocking, or both to fix two surfaces together. Adhesion is one of the most important characteristics of film systems.

? Compression tests can be performed on materials for multiple purposes. Depending on the type of material, compressive properties may be quite different from tensile properties.

? Tests that characterize material properties under constant strain or stress conditions fall into the category of creep and stress relaxation. These tests can provide important information about the properties of materials or components under long-term conditions.

? Drop mechanical testing is also called impact testing; it is usually performed as part of the hardware qualification or design process. The information obtained during the impact test can improve the survivability of the product and verify its performance in service.

? Ductility can also be called bending or bending test. Ductility refers to the ability to undergo plastic deformation during stretching or bending before breaking.

? Fatigue tester can also be called dynamic tester. The fatigue tester measures the fatigue strength or destructive resistance of materials under controlled cyclic deformation conditions.

? The two most commonly used methods in impact testing are Charpy and Izod. The impact test measures the energy absorbed by the sample before it ruptures. This energy consists of several energy contributions, including the energy absorbed by the impact machine through vibration after the initial contact with the sample and the energy loss of the pendulum during hammering (in the pendulum impact During the test) the total energy consumed by the impact of the sample and the deformation and fracture of the sample.

? Shear strength is defined as the maximum stress that a material can withstand before shear failure. The calculation of shear strength depends on the test method.

? Tensile mechanical testing is the most common type of material and product testing. From quality control to research and development, most laboratories basically need to characterize and report tensile test performance.

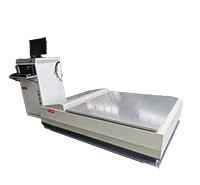

? The vibration test system is used to evaluate the design purpose of products and packaging, and to simulate the vibration effect of product transportation. - Technical indicators

- User interface options for mechanical test equipment include analog or digital local interfaces, computer interfaces, serial or parallel communications, and application software. Display options for mechanical test equipment include analog meters, digital readouts, and video displays. Other output options include analog voltage, pulse signal, analog current, and switch or relay. Important environmental parameters to be considered for mechanical testing equipment include working temperature and working humidity。

-

- Contact information of each office:

-

- Shanghai office (China)

-

- Postcode: 100083

-

- Tel: +86 15360508198

- Contact: Mr. Chen

-

- Chengdu Office? (China)

-

- Postcode: 610000

-

- Contact: Mr. Huang

-

- Guang Zhou office (China)

-

- Postcode: 510000

-

- Tel: +86 13302301691

- Contact: Miss Xia

-

? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? Get Quotes

Please fill in your contact information and the product you need, we will have a specialist to contact you quickly.

Service Hotline:

+86 020-84849616

service hours:

Monday to Saturday,

8:00—12:00, 13:30-5:30

Mail:

myf020@126.com

Service Hotline:

020-84849616

service hours:

Monday to Saturday,8:00—12:00, 13:30-5:30

Mail:

myf020@126.com

Guangzhou Meiyifeng Test Equipment Co., Ltd.:

Guangzhou Meiyifeng Test Equipment Co., Ltd. is located at the foot of the beautiful Lianhua Mountain in Guangzhou. It is a professional high-tech enterprise integrating laboratory equipment, system engineering research and development, manufacturing, sales and service.

It mainly produces test and testing equipment related to temperature and humidity, acoustics, optics, electricity, mechanics, etc. and product reliability testing. With advanced processing equipment, exquisite manufacturing technology, strict management system, strong technical strength and good After-sales service to meet the different needs of our customers. Products comply with GB, GJB, ASTM, DIN, JIS, CNC, UL, MIL, IEC, ISO and other standards, and can also design, develop and manufacture non-standard products according to customer requirements.

Contact (Headquarters):

Tel: +86 020-84849616

Fax: +86 020-84868859

Address: Pushan Industrial Zone, Daling Village, Shilou Town, Panyu District, Guangzhou City, China

Quick Navigation:

Zalo QR code (instant reply):

Official Whatsapp account:

Copyright Guangzhou Meiyifeng Testing Equipment Co., Ltd.